Share page?

[ssba]

For many homeowners, building on a sloping site is often unavoidable when building your dream home. You want to be elevated and you want a view, so building on a sloping piece of land often comes with the territory. Other benefits of building on sloping land include more natural sunlight, better natural drainage and ventilation, the opportunity for more interesting home designs due to the extra space, and ultimately a property with higher value.

Building on a sloping site can be challenging and costly, but it can be made easier and cheaper by choosing the right type of building materials. But what constitutes a sloping site?

Steep sites are classified as difficult sites. A sloping site is generally any block of land with a slope of more than 6 degree, generally speaking, the steeper the slope the more complex the design of the home will be and the more it will cost.

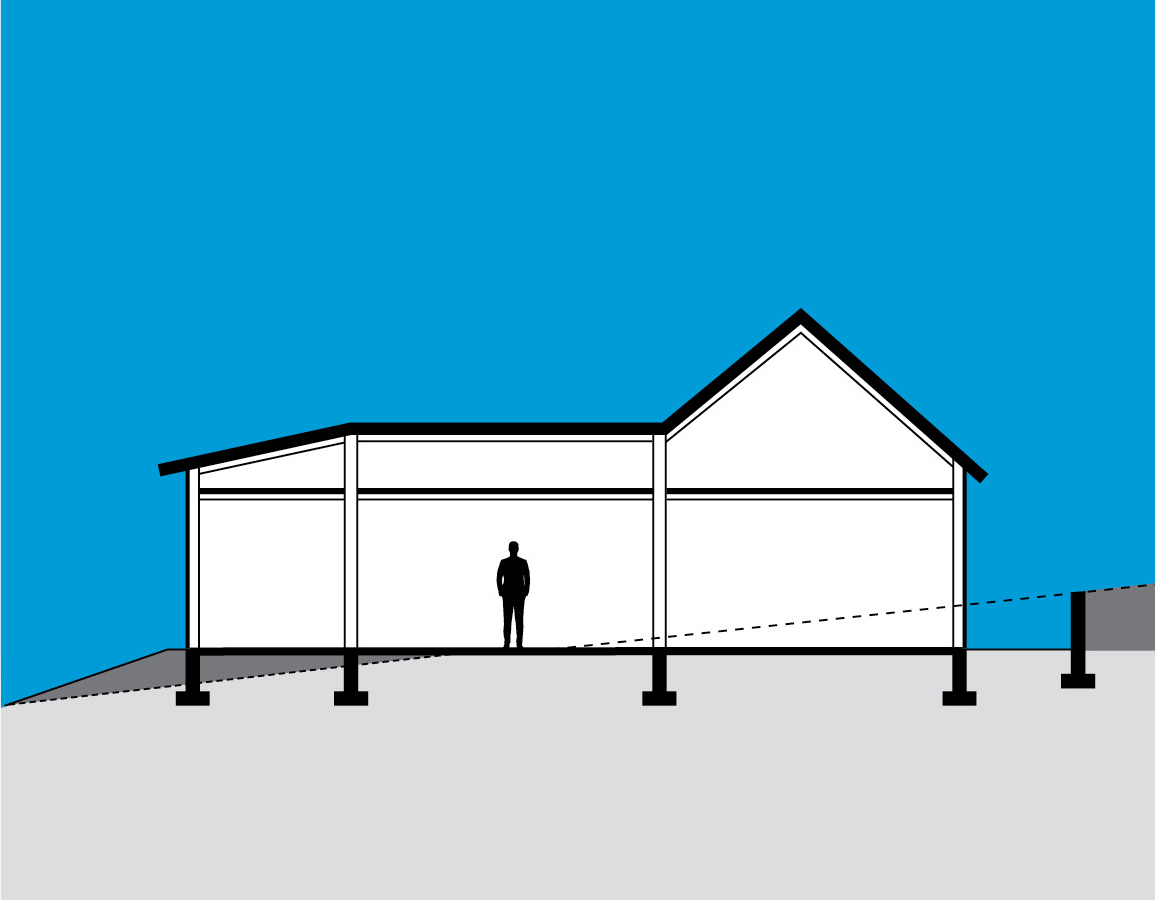

Flat to slightly sloping sitesSingle slab on ground construction is only suitable for a site slope up to seven per cent. Slopes between seven and 10 per cent, should accommodate some level change within the building footprint.

Flat to slightly sloping sitesSingle slab on ground construction is only suitable for a site slope up to seven per cent. Slopes between seven and 10 per cent, should accommodate some level change within the building footprint. Moderate slopeFor slopes between seven and 20 per cent, stepping two or more slabs or using part slab/part post or beam construction would be suitable to handle the slope. Single slab on ground construction is not recommended

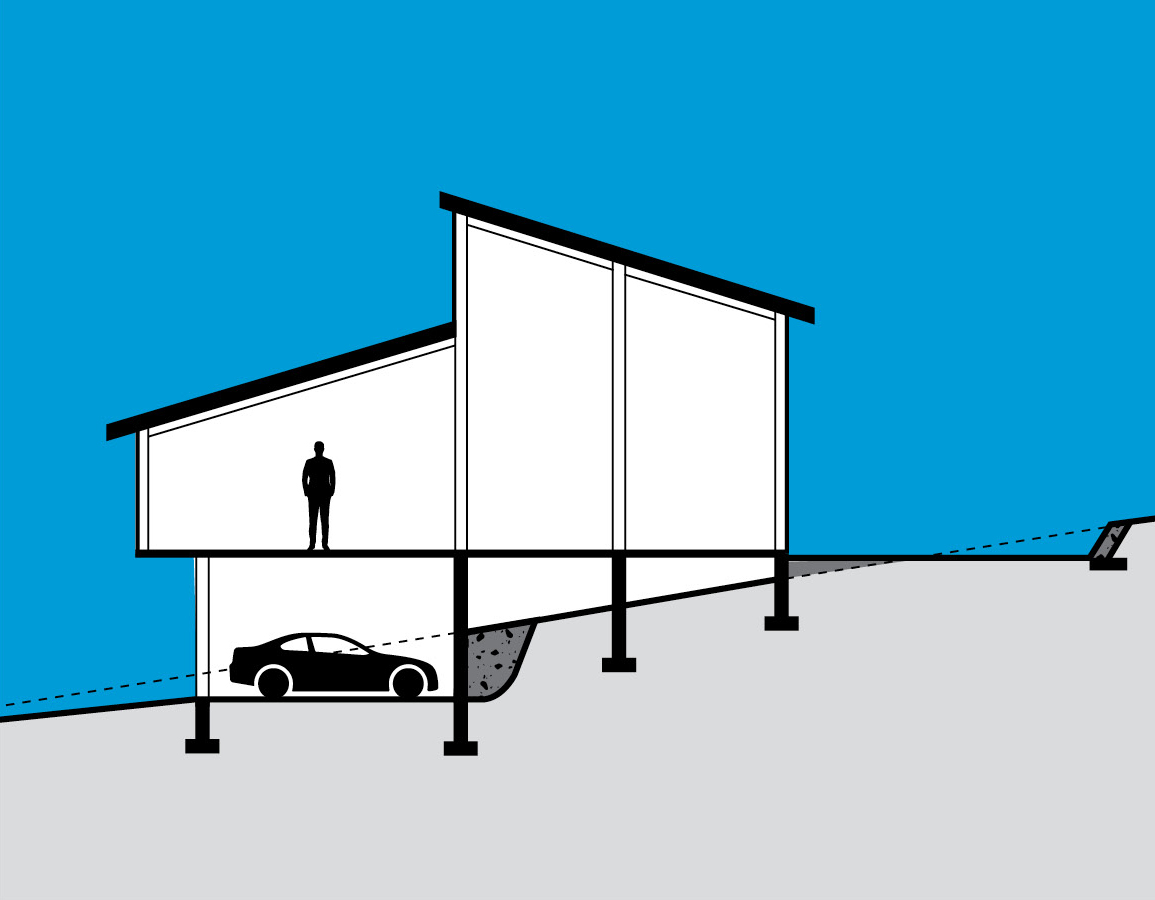

Moderate slopeFor slopes between seven and 20 per cent, stepping two or more slabs or using part slab/part post or beam construction would be suitable to handle the slope. Single slab on ground construction is not recommended Steep slopeFor slopes between 20 and 33 per cent, post and beam construction should be used which steps with the site. This may include a lower part level with a concrete slab. Single slab on ground construction should not be used.

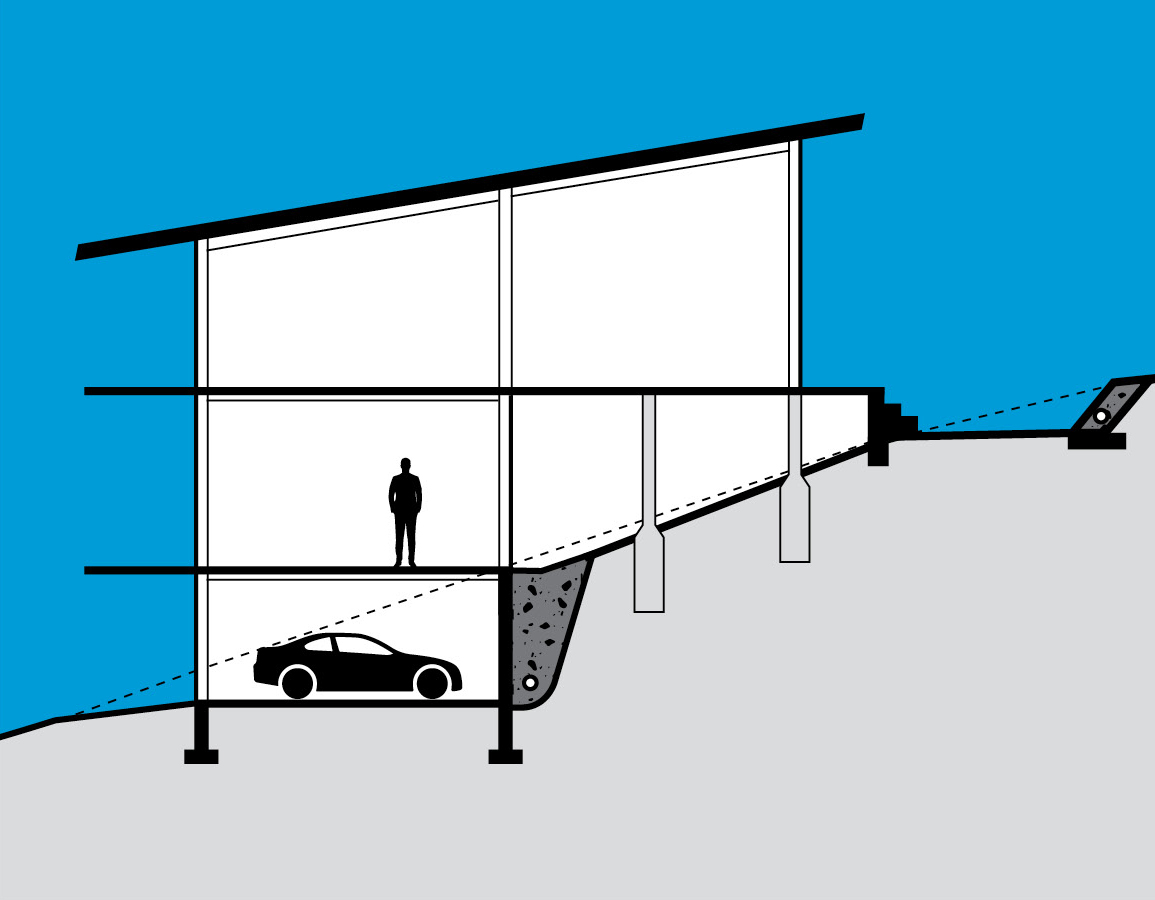

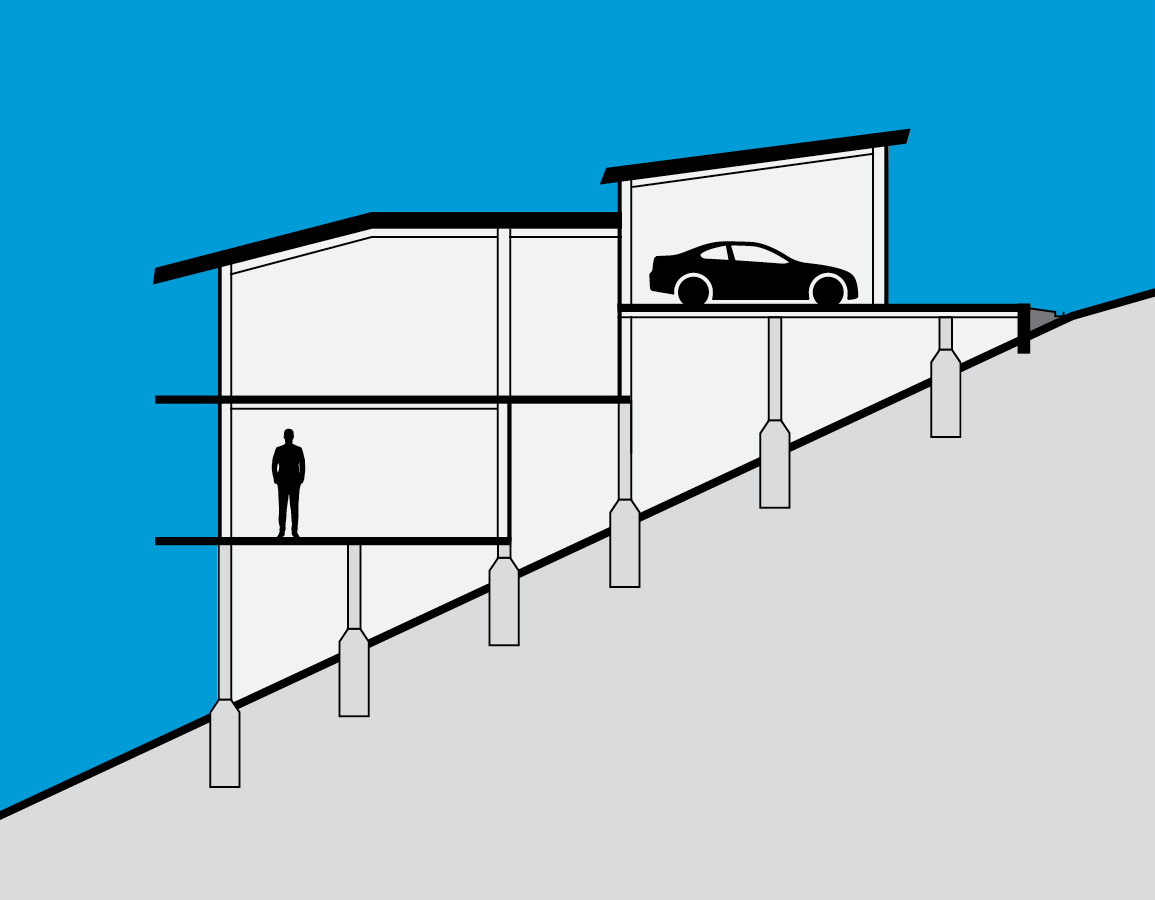

Steep slopeFor slopes between 20 and 33 per cent, post and beam construction should be used which steps with the site. This may include a lower part level with a concrete slab. Single slab on ground construction should not be used. Extreme slopeFor slopes more than 33 per cent, suspended or pole construction techniques are required. This degree of slope isalt=”sll” more suited to a downslope configuration. Driveway access is generally too difficult on steep upslope lots which require large batters/retaining walls and sometimes a curving driveway.

Extreme slopeFor slopes more than 33 per cent, suspended or pole construction techniques are required. This degree of slope isalt=”sll” more suited to a downslope configuration. Driveway access is generally too difficult on steep upslope lots which require large batters/retaining walls and sometimes a curving driveway.The key to minimising the cost of building on a sloping site is to work with the site as much as possible rather than against it.

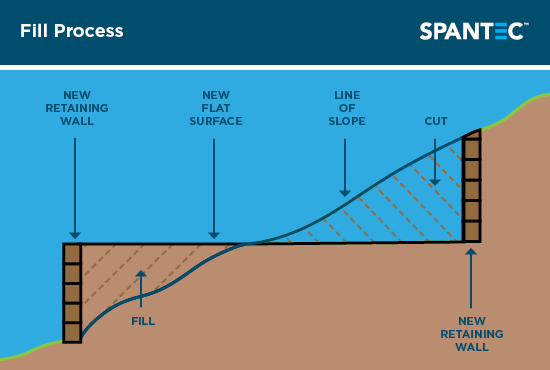

Cutting and filling, the process of creating a flat site on sloping land (see below) is expensive and can create significant additional costs for retaining walls or spoil removal. One of the largest issues is that hills are generally made of rock, you can expect the ground of a sloping site to be a lot shallower than usual, it doesn’t take much digging to hit rock, with this in mind you want to try and minimise the amount of excavation that’s performed to keep costs down.

Home owners or builders can often completely avoid these issue by using a large spanning bearer and joist system. This may include a steel raised floor system that follows the slope of the land in a single storey, split level or multi-level construction.

As an alternative to pouring a concrete slab on the ground, a raised floor system can enable even more ability to work with the natural slope on your block of land.

The benefits of using a raised floor on a sloping site include:

When choosing a raised floor system for your new home, consider the following critical factors:

Spantec is a long-time supplier of innovative steel building products for home builders across Australia. Our Boxspan steel floor kits are uniquely designed to meet all the requirements of building on sloping sites while also offering durability and installation efficiencies. With a Boxspan steel floor kit from Spantec you will get:

Our Boxspan Steel Flooring System is a unique solution for efficiently and accurately meeting the challenges of building on sloping sites. We do this by providing:

The Boxspan Steel Flooring System is a unique solution that takes the pain out of building on sloping sites. Just ask Joe Simundza of Southern Belle Constructions, who used the system to successfully build a family home on a site with a severely sloping fall of 22-degree and up to 30 degrees in places.

A self-confessed “old-school carpenter and builder”, Simundza had to think outside the box to deliver the project. He chose to use the Boxspan Steel Flooring System from Spantec, and never looked back, and his challenging build was simplified.

“This process saved us many days and a lot of back-breaking work [and was possible] because the beams are so much lighter than what I have used on other sites,” he says. “The Boxspan system saved us around four to five days per floor, or about 16 to 20 days for all the floors — and we saved about $20,000 on machinery.”

Andrew and Rachel Cummins were building their rural dream home in the Hawkesbury region northwest of Sydney with a floor and deck structure that would cover 690m2. Their chosen site had a slope which fell approximately 2.5 degress north across the width of the home, was in a bushfire and termite prone area, and was also found to contain Hawkesbury sandstone. All of these challenges required them to find an alternative to timber for their wall frames, roof trusses, sub floor and deck structure.

“As we wanted to use a tongue-and-groove floor over a plywood base, we required a sub-floor that had no bows or twists, was made of steel, and provided a solution that gave us peace of mind in the location in which we were about to build,” Andrew said.

“Spantec had a large selection of different sized beams, which worked well with my design, and offered us a design package that came with a full set of site drawings, which we found to be very accurate. I found the service to be excellent.”

-or- Get a quote