Share page?

[ssba]

With Australian cities and close towns becoming more densely populated, people are looking to build in more remote areas and to build their dream homes. Kit homes give owner-builders the freedom and flexibility to start with a standard design, then put their touches on it to make it uniquely theirs.

Kit Homes can also be a more economical way of building a custom design, and it provides a more hands-on experience for the owner-builder, meaning they can build their own home with minimal trades and have an incredible feeling of accomplishment once complete.

As it becomes a more popular way to build in Australia, Kit Home companies have begun to spring up around the nation, and with the growth in companies comes an expanding array of designs to start that dream home journey.

Spantec have been in business for over 30 years and we have worked extensively with Australia’s leading kit home companies. This experience has enabled us to be flexible with designs, accommodating changes to basic designs if an owner-builder would like to customise their house.

Some of the other benefits of working with Spantec for the subfloor frame of a kit home include:

Owner-builders Jason and Deborah Ahrens recently used the Boxspan sub-floor system including the ezipier adjustable steel piers, supplied by Spantec, to build the floor frame for their dream kit home in Tasmania. Jason opted for a kit home because he wanted to enjoy the experience of building his own home from scratch. The site is steep, overlooking an orchard, with distant views of the Derwent River and Port Arthur. The steep site presented no problem for the Boxspan flooring system, which eliminates the need for cutting, filling and compaction. This means there is no need to repair the site with expensive landscaping and retaining walls, an often-overlooked cost in the building process.

“We always knew that we were going to use the Boxspan sub-floor system as I had helped my dad on a few Boxspan projects before,” Jason said. “We knew the site was awkward to begin with, but we loved the views.

“I found it extremely easy and I would not hesitate to use the Boxspan sub-floor system again.” Jason said. “I did virtually 95 per cent of the work on my own but I needed a mate to help with those 8-metre-high posts at the front of the deck. “Installation of the Boxspan sub-floor system and the Ezipiers went smoothly, despite the challenges with delivery due to our location.” Jason said.

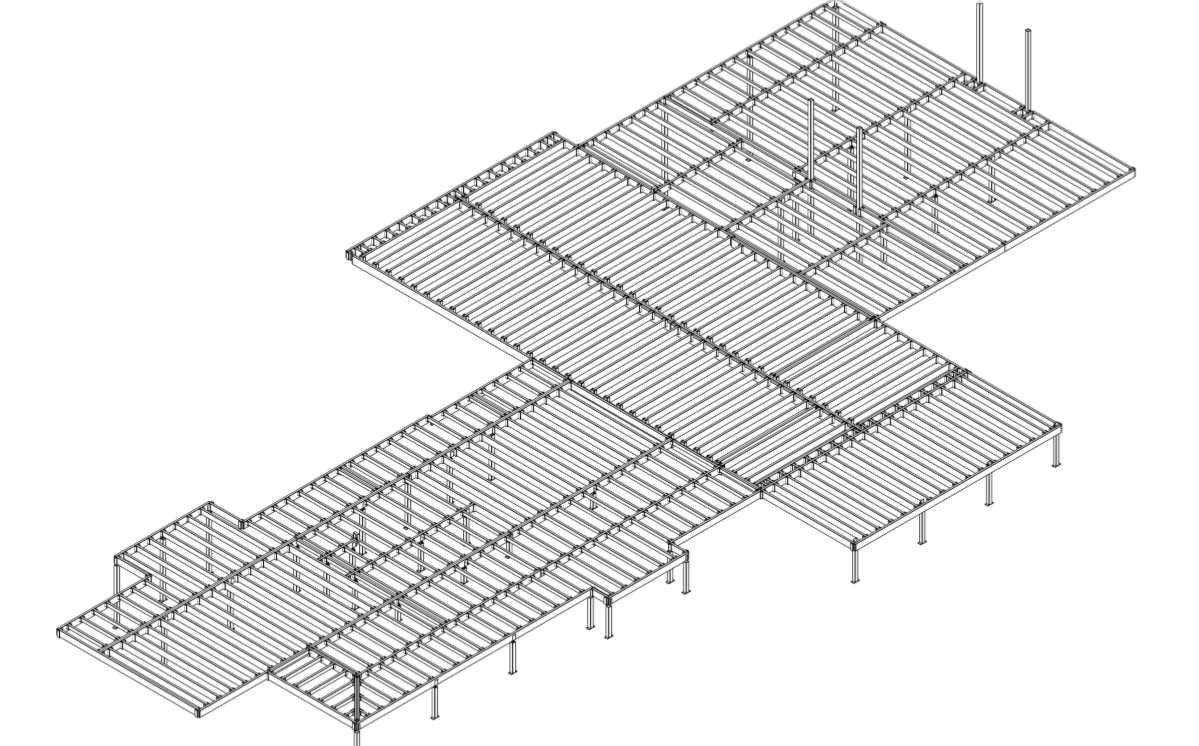

Boxspan steel floor framing is a high-quality sub-floor system that is lightweight and quick to install. The floor frames are designed and manufactured by Spantec Systems, ready to assemble.

This allows owner-builders to get their dream home off to a flying start by easily overcoming the first challenge of constructing a sub-floor framing system. The Boxspan system is strong yet very light. Being made from steel, it is non-combustible and termite proof, which make it ideal for building in the bush. For Jason, these added benefits became a necessity, making the Boxspan System the ideal building product.

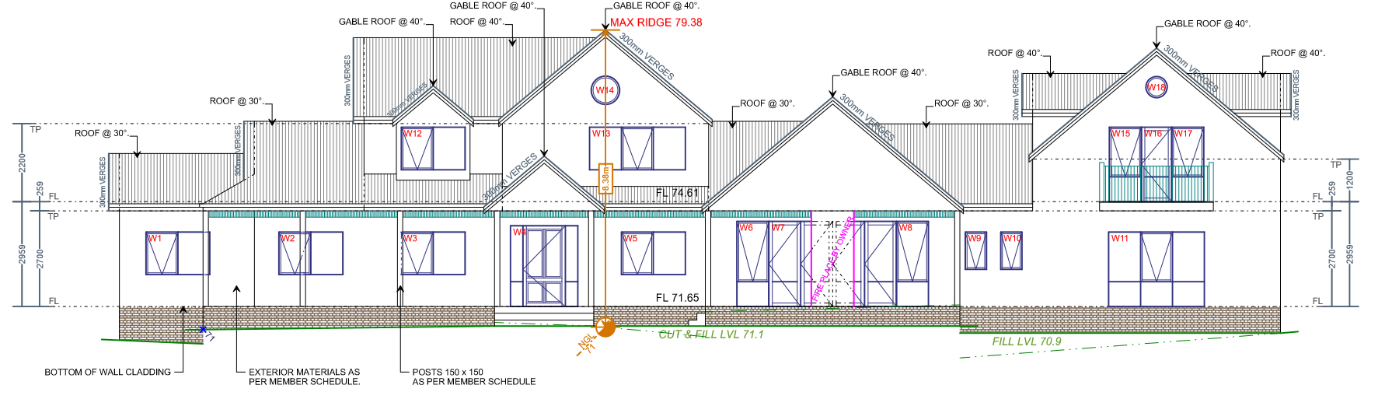

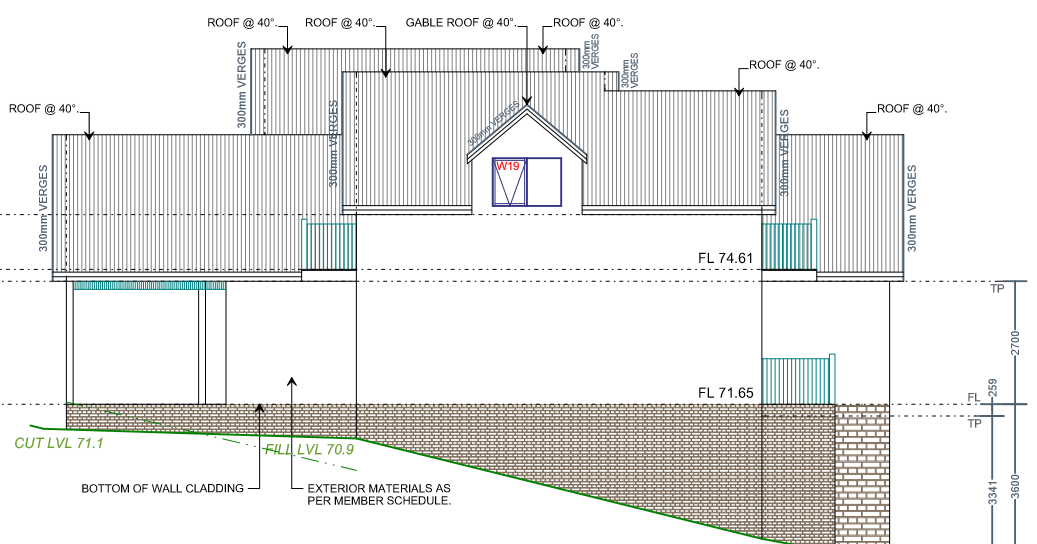

David Anderson had a vision for his beautiful, sloping site and had selected the luxurious Harkaway kit home that he wanted to build to make that dream a reality, but the site was also in a high termite area and bushfire zone.

David went searching the web to find a sub floor system that would work for his home and soon came across the Spantec website.

“After brief researching, I came across Spantec,” David said. “They looked like a professional outfit, so I made contact with them.

“A sales team member gave me a quick rundown on the products and process [and] from there I went to their office at Braemar with my plans for a meeting to discuss my build further. The service I received was great, the sales and design team were very receptive. The steel system on offer was fantastic – as I was taking on the build myself, I wanted something strong and simple to put together [and] Spantec ticked all the boxes. I found [their] final stage construction drawings really easy to understand. We could not be happier with the result.”

Spantec provided a full supply and construction drawing package, no engineering was required by Spantec, but we worked closely with David’s appointed project engineer. There were three decks and multiple direction floors that required different spans and pier grids within this project. Having a large selection of different sized bearers and joists within the Boxspan range proved a huge benefit and allowed the whole floor frame to come together as one complete cost-effective kit.

“The material arrived onsite packed nice and neat, all the fixing and ezipier bags were labelled, Spantec even had a full set of A3 drawings printed for me in a bag,” David said. “All bearers and joists were cut to size and they were labelled relating back to the construction drawings, due to a lot of different sizes the labelling made sorting onsite extremely easy.”

-or- Get a quote